Basic Info.

Processing Technics

Crushing-before-Mixing

Screen Mesh

Without Screen Mesh

Pellet Mill Type

Ring Die Pelleter

Condition

New

Applicable Materials Shape

Granular

Warranty

One Year

Transport Package

Wooden Case

Specification

According to different type

Trademark

hanpai

Origin

China

HS Code

8436990000

Production Capacity

3000 Pieces/Year

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 50.00cm

Package Gross Weight

150.000kg

Product Description

1.Products show

1).What is a ring die ?

Huge ring fittings with porous surfaces are known as "ring die." Ring molds must be assembled with extreme dimensional accuracy due to their thin walls and dense holes. It is one of the most crucial and easily worn pellet mill accessories. To ensure the ring die's resistance to wear and corrosion, high carbon, high chromium steel (4Cr13) and alloy steel are primarily used in its construction. To ensure the ring die's hardness, it is subjected to vacuum quenching or high temperature carbonizing. Additionally, the ring die must have an appropriate die hole configuration and compression ratio based on the product that will be manufactured in order for the ring die to operate more productively while using the same opening area.

2).Raw material :

Our materials are made using high-quality steel that undergoes a forging process to obtain the desired properties. We prioritize the raw materials come from reliable suppliers. Through the forging technique, the raw material undergoes a controlled heating and shaping process, resulting in materials with enhanced strength, durability, and structural integrity. Our commitment to using top-quality raw materials ensures that our products meet the highest standards and offer exceptional performance. With our carefully selected materials and rigorous manufacturing processes, we strive to deliver reliable and superior products to our customers.

3).Specification of ring die:

We can provide ring die for all major brands of granulator, such as ANDRITZ, CPM, Muyang(FAMSUN), Buhler, Zhengchang, IDAH, etc.

We can design various rings die according to the drawings and we can c

Specification parameters of feed mills ring die:

•Material:Quality chromium Steel

•Machining aperture:0.8mm up to 18mm

•Outer diameter of workpiece:300mm up to 1200mm

•Inner diameter of workpiece:200mm up to 900mm

•Surface hardness:HRC 52-56

•Ring die wall thickness:15mm up to 100mm

•Compression ratio:according to user demand

4).Finished products packing

5).Our ring die advantages

•Good finish of ring die mill hole surface, hole homogeneous distributed, high hardness.

•Short time running-in, smooth production, non-flushing (excluding aperture 0.8-2.0), directly used on the pellet mills. 2 hours running reaches the maximum production per hour.

•Good forming, fine finish, high uniformity, low powder content, no material dumping.

•High production per hour, long service life. Production per hour and overall are significantly higher than peer level in the same scale.

•Energy saving. Stable current, low power consumption.

•Light weight and easy loading.

2. Applications of Hanpai Ring Dies

1) Applications show

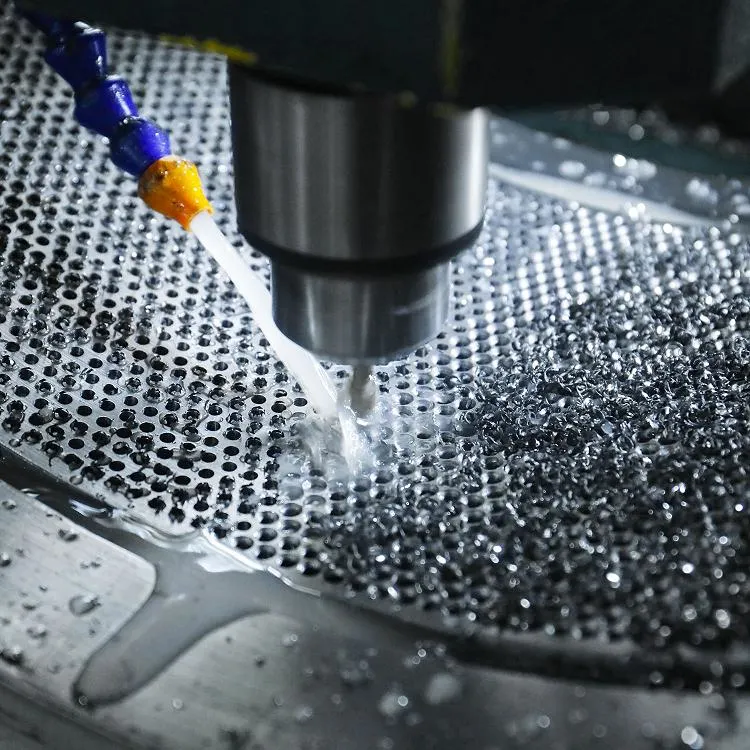

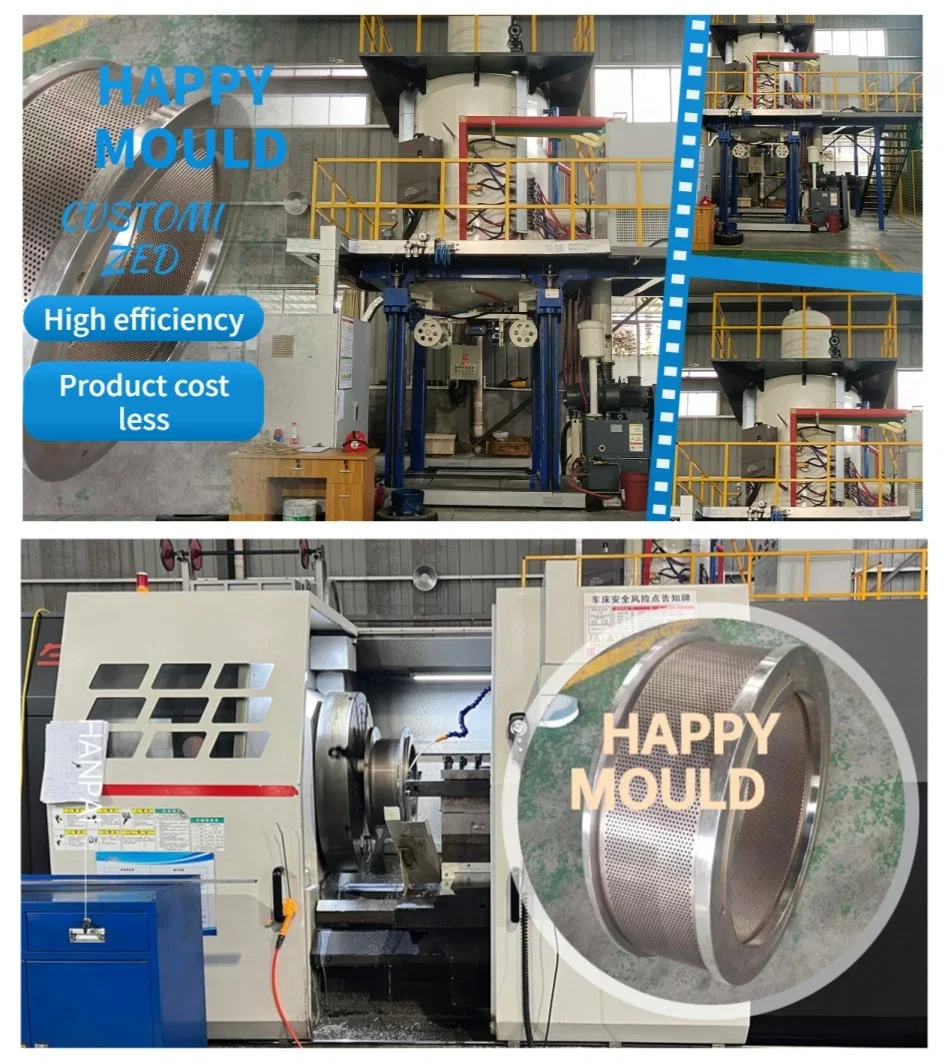

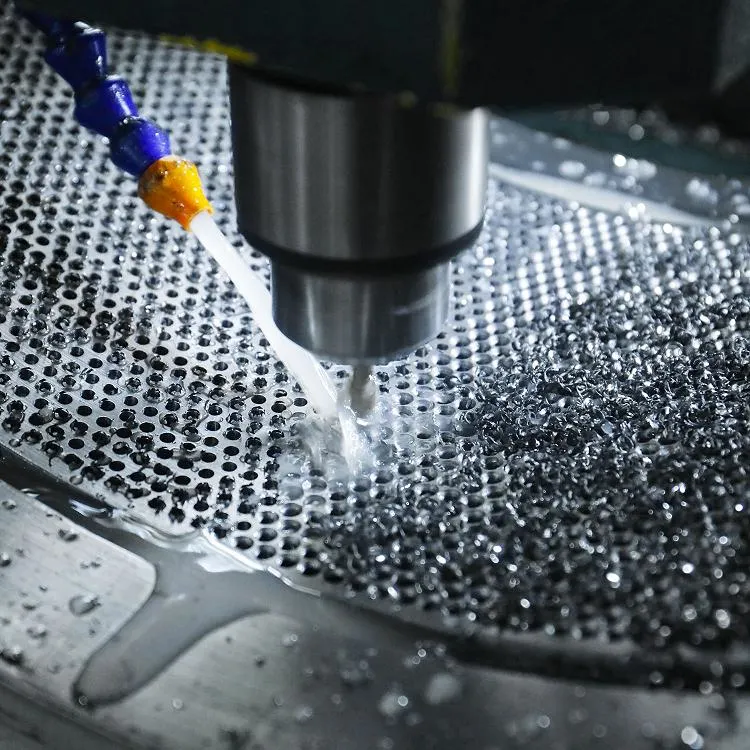

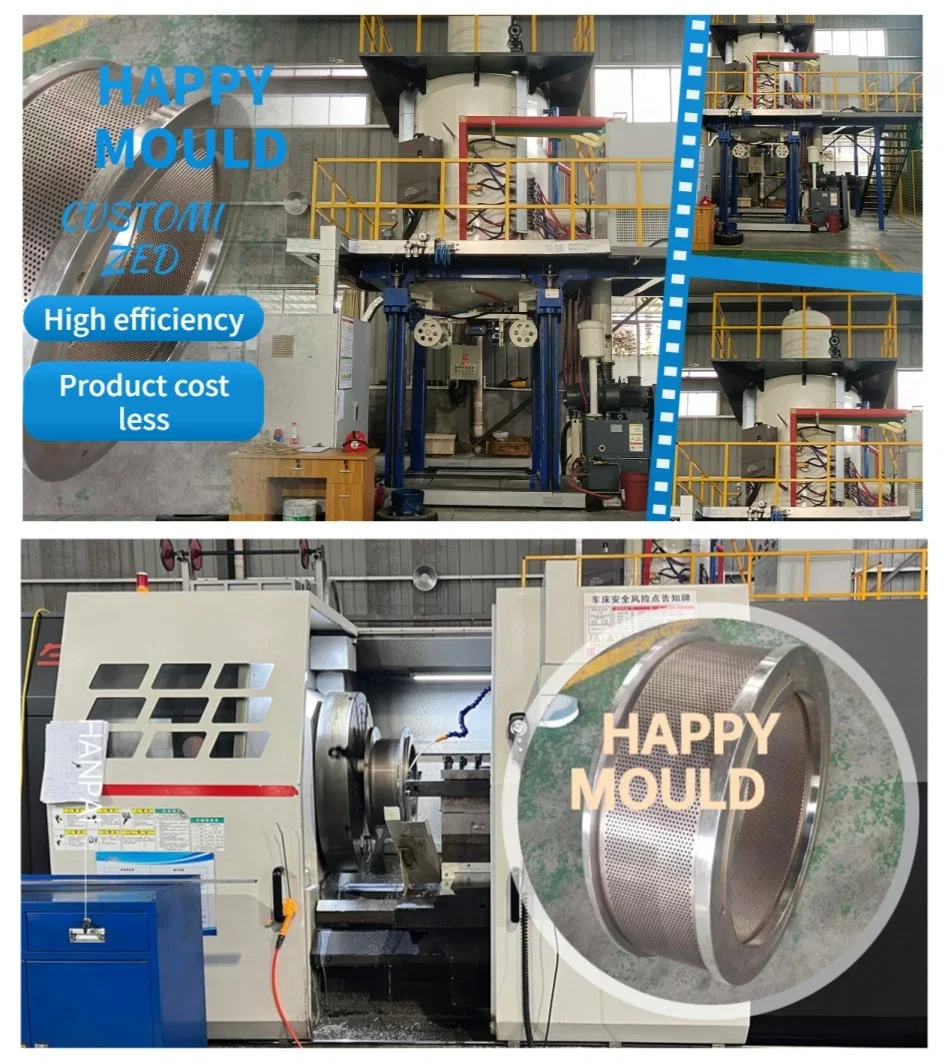

3. Our company capabilities show

1.)Our production facilites show

2.)Quality control

Happy Mould use high quality steel, CNC deep hole drilling machine,vacuum quenching furnace and other advanced equipment and unique process; effectively solve problems between the production efficiency and particle quality, hole ratio and service life; effectively solve the problem of dumping material of small aperture fish feeds ring die, uneven length of particle, high percentage of powered pellets, long time cost in run-in; greatly improve production efficiency, improve particle quality, improve yield, reduce production cost.

3.)Our qualitifications and certicates

★ 10 years of experience commited into making feed machine accessories ring die

★ Customized product based on any of our customer's need

★ Produced by using high quality X46cr13 Stainless Steel

★ Exquisite craft,high smoothness, nice appearance, high capacity.

★ Strickly inspection of quality control

In 2017, we were honored as scientific and technological enterprises in Zhejiang Province.

4.Our environment

FAQ:

1,Q:Are you a mould manufacturer? How long is the production cycle of the ring die?

A:We are a manufacturer, specializing in manufacturing ring mold production, our ring mold production cycle in 30-60 days

2,Q:How long can your ring die be used?

A:Our ring die has long service life.The service life time is above 1000 hours.

3,Q:Which foreign customers have purchased your ring mold?

A:Yes, we have.Our company has established business relationships with customers in South Africa,,Vietnam, Korea,Indonesia, New Zealand, India, etc

4,Q:What materials do you usually use for your ring mold?

A:The materials used in our company's ring mould are all stainless steel, which is measured by European standards

5,Q:How far is your company from the port?

A:We are only 200 kilometers from Shanghai Port

6,Q:What information do you need to provide to purchase your ring mold?

A:As long as you tell us the brand and model of your pelletizer, aperture and compression ratio, we will produce precise pelletizer spare parts for you

1).What is a ring die ?

Huge ring fittings with porous surfaces are known as "ring die." Ring molds must be assembled with extreme dimensional accuracy due to their thin walls and dense holes. It is one of the most crucial and easily worn pellet mill accessories. To ensure the ring die's resistance to wear and corrosion, high carbon, high chromium steel (4Cr13) and alloy steel are primarily used in its construction. To ensure the ring die's hardness, it is subjected to vacuum quenching or high temperature carbonizing. Additionally, the ring die must have an appropriate die hole configuration and compression ratio based on the product that will be manufactured in order for the ring die to operate more productively while using the same opening area.

2).Raw material :

Our materials are made using high-quality steel that undergoes a forging process to obtain the desired properties. We prioritize the raw materials come from reliable suppliers. Through the forging technique, the raw material undergoes a controlled heating and shaping process, resulting in materials with enhanced strength, durability, and structural integrity. Our commitment to using top-quality raw materials ensures that our products meet the highest standards and offer exceptional performance. With our carefully selected materials and rigorous manufacturing processes, we strive to deliver reliable and superior products to our customers.

3).Specification of ring die:

We can provide ring die for all major brands of granulator, such as ANDRITZ, CPM, Muyang(FAMSUN), Buhler, Zhengchang, IDAH, etc.

We can design various rings die according to the drawings and we can c

ustomize according to customer requirements.

Specification parameters of feed mills ring die:

•Material:Quality chromium Steel

•Machining aperture:0.8mm up to 18mm

•Outer diameter of workpiece:300mm up to 1200mm

•Inner diameter of workpiece:200mm up to 900mm

•Surface hardness:HRC 52-56

•Ring die wall thickness:15mm up to 100mm

•Compression ratio:according to user demand

| Specification Type | Hole Diameter | Working Width | Designed Output |

| IDAH 530F | 0.8 | 193 | 1.0t-1.5t/h |

| FAMSUN 600 | 170 | 0.8-1.2t/h | |

| ANDRITZ 520 | 178 | 0.8-1.2t/h | |

| IDAH 530F | 1.0 | 193 | 2.5t--3.9t/h |

| FAMSUN 600 | 170 | 2.2t-3.5t/h | |

| ANDRITZ 520 | 178 | 2.2t-3.5t/h | |

| IDAH 530F | 1.2 | 193 | 2.8t-4.6t/h |

| FAMSUN 600 | 170 | 2.5t-4.0t/h | |

| ANDRITZ 520 | 178 | 2.5t-4.0t/h |

| Feed Varieties | Hole Diameter | Compression Ratio |

| Poultry&livestock feed | Φ2.0-Φ4.5 | 1:9-1:20 |

| Shrimp Feed | Φ0.8-Φ2.0 | 1:20-1:35 |

| Fish feed | Φ1.5-Φ5.0 | 1:10-1:25 |

| Crab feed | Φ1.5-Φ5.0 | 1:15-1:26 |

| Biomass and Fertilizer | Φ5.0-Φ18.0 | 1:4-1:10 |

| Cattle and sheep feed | Φ4.5-Φ10.0 | 1:6-1.12 |

| Feline feed | Φ1.6-Φ3.5 | -- |

4).Finished products packing

5).Our ring die advantages

•Good finish of ring die mill hole surface, hole homogeneous distributed, high hardness.

•Short time running-in, smooth production, non-flushing (excluding aperture 0.8-2.0), directly used on the pellet mills. 2 hours running reaches the maximum production per hour.

•Good forming, fine finish, high uniformity, low powder content, no material dumping.

•High production per hour, long service life. Production per hour and overall are significantly higher than peer level in the same scale.

•Energy saving. Stable current, low power consumption.

•Light weight and easy loading.

2. Applications of Hanpai Ring Dies

1) Applications show

3. Our company capabilities show

1.)Our production facilites show

2.)Quality control

Happy Mould use high quality steel, CNC deep hole drilling machine,vacuum quenching furnace and other advanced equipment and unique process; effectively solve problems between the production efficiency and particle quality, hole ratio and service life; effectively solve the problem of dumping material of small aperture fish feeds ring die, uneven length of particle, high percentage of powered pellets, long time cost in run-in; greatly improve production efficiency, improve particle quality, improve yield, reduce production cost.

3.)Our qualitifications and certicates

★ 10 years of experience commited into making feed machine accessories ring die

★ Customized product based on any of our customer's need

★ Produced by using high quality X46cr13 Stainless Steel

★ Exquisite craft,high smoothness, nice appearance, high capacity.

★ Strickly inspection of quality control

In 2017, we were honored as scientific and technological enterprises in Zhejiang Province.

4.Our environment

FAQ:

1,Q:Are you a mould manufacturer? How long is the production cycle of the ring die?

A:We are a manufacturer, specializing in manufacturing ring mold production, our ring mold production cycle in 30-60 days

2,Q:How long can your ring die be used?

A:Our ring die has long service life.The service life time is above 1000 hours.

3,Q:Which foreign customers have purchased your ring mold?

A:Yes, we have.Our company has established business relationships with customers in South Africa,,Vietnam, Korea,Indonesia, New Zealand, India, etc

4,Q:What materials do you usually use for your ring mold?

A:The materials used in our company's ring mould are all stainless steel, which is measured by European standards

5,Q:How far is your company from the port?

A:We are only 200 kilometers from Shanghai Port

6,Q:What information do you need to provide to purchase your ring mold?

A:As long as you tell us the brand and model of your pelletizer, aperture and compression ratio, we will produce precise pelletizer spare parts for you