Basic Info.

Model NO.

TLCM

Transport Package

Wooden Box

Specification

customized

Trademark

TFZD

Origin

Xinxiang Henan; China

HS Code

8428399000

Production Capacity

2000pieces/Years

Product Description

PRODUCT DESCRIPTION

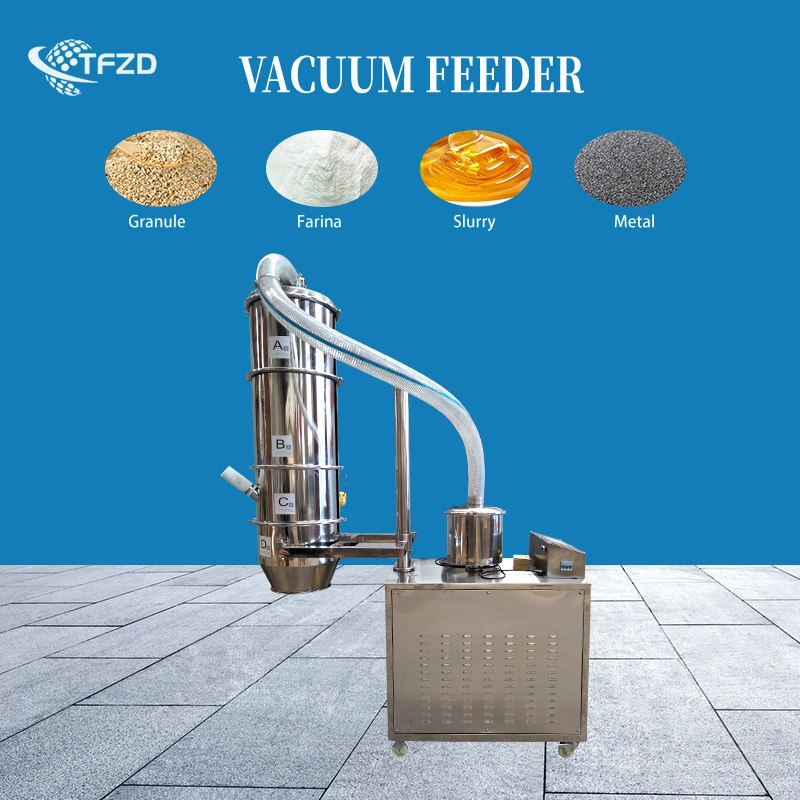

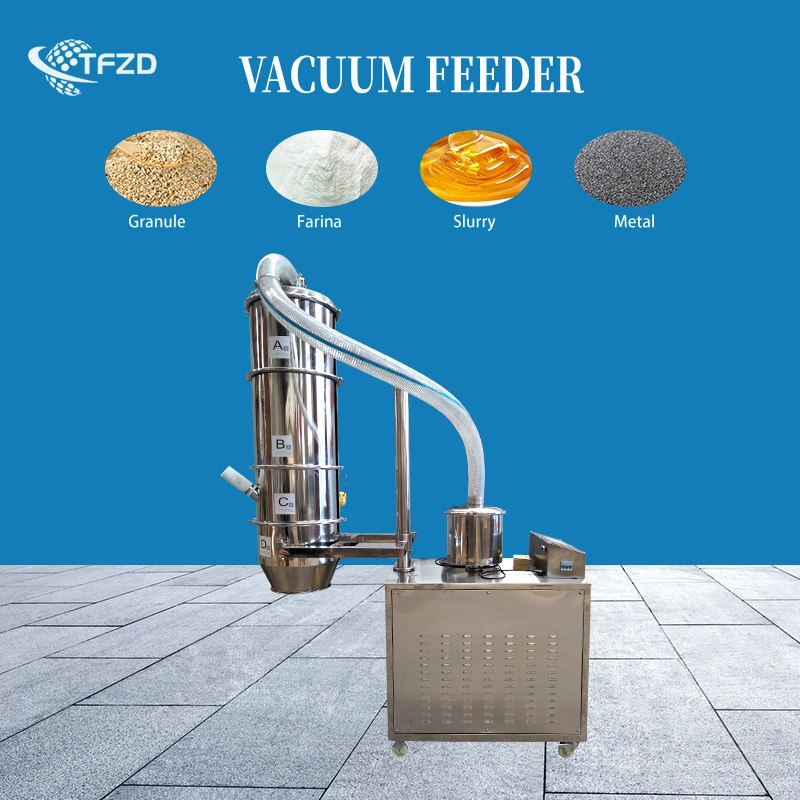

Powder Grain Conveying Machine Vacuum Feeding Conveyor System

The TLCM vacuum feeder uses a vacuum pump to pump air, so that the inlet of the suction nozzle and the whole system are in a certain vacuum state. The powder and particles are sucked into the nozzle along with the outside air to form a material air flow, and then reach the hopper through the suction pipe. Separation of gas and material in the middle. The separated material enters the receiving equipment. Conveying and discharging are accomplished through the continuous opening and closing of the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is controlled by the control center.

The vacuum feeder is equipped with a compressed air blowback device. Every time the material is discharged, the compressed air pulse blows back the filter to knock down the powder adsorbed on the surface of the filter, so that the suction can operate normally.

PRODUCT ADVANTAGES

1-Reduce environmental and personnel pollution to materials and improve cleanliness.

2-It occupies a small space, and can complete the powder conveying in a narrow space, making the working space beautiful and generous, not limited by the distance.

3-The entire conveying process is carried out in a closed system, and no powder leakage will occur.

4-Easy to visually inspect, the equipment has no gaps or dead corners that are easy to accumulate materials, and the surface is easy to visually inspect.

5-Reduce labor intensity and improve work efficiency.

APPLICATION

TLCM vacuum conveying machine is extensively applied in pharmaceutical industry, food industry, chemical industry and agriculture. Vacuum feeding machine can be used to convey bulk pharmaceutical chemicals, powder material, granular material, mixed material, tablets, afterbirth pills, capsules, additives, raw materials, candy, afterbirth sugar pill, cocoa powder, gourmet powder, crystal, etc. This vacuum conveying machine can also be used to convey chemical raw materials, industrial raw materials, dyes, agricultural bulk material, etc .

FEATURES

1. The material suction nozzle entrance and the whole system of ZKS vacuum feeding machine are in a certain vacuum state. Powder or particle material and outside air can be suctioned into the material nozzle and form material air flow. Through the suction material tube, it reaches the hopper where air and material will be separated. After separation, material enters the material receiving equipment.

2. This vacuum conveying machine is installed with compressed air reverse blowing device. While putting material, compressed air pulse reversely blows the filter and fetches down the powder absorbed on the surface of filter, thus ensures material suction is in normal running.

MATERIALS USAGES SCENARIO

ABOUT TRANSPORTATION

After you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send the customer the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent the customer from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself.

COMPANY PROFIL

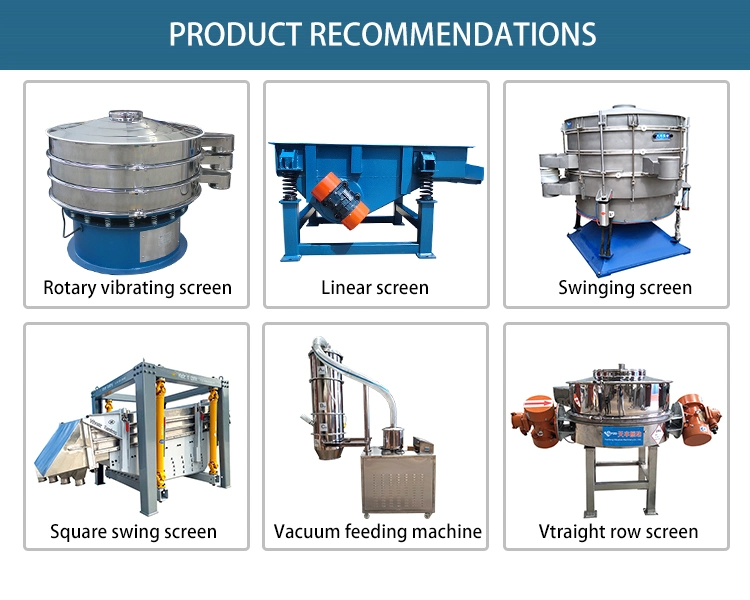

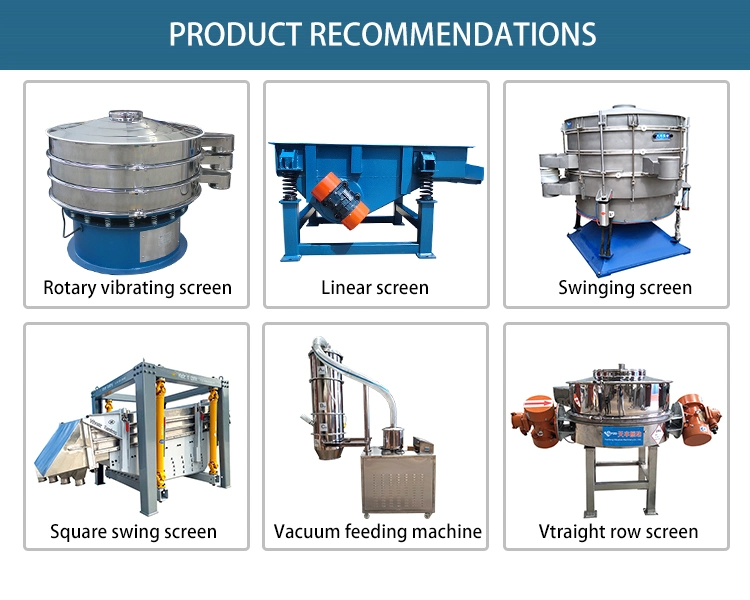

Xinxiang Tianfeng Vibrating Machinery Co., Ltd. (formerly Xinxiang Tianfeng Vibrating Machinery Factory) is a comprehensive enterprise specializing in the research, development, manufacturing, and sales of mechanical equipment such as vibrating screen, separation, crushing, and conveying for more than 30 years. The company mainly produces Vibrating screens, ultrasonic vibrating screens, test screens, oscillating screens, linear screens, airflow screens, feeders, bucket elevators, conveying equipment, and other mechanical equipment. This equipment features stable and reliable operation, simple operation, convenient maintenance, low noise, low energy consumption, large output, and high precision; The screen mesh has the advantages of no blockage, no flying powder, no liquid leakage, etc. The products are widely used in food, medicine, chemical industry, metallurgy, abrasives, plastics, glass, paint, pollution control, and other industries, with high efficiency, large processing capacity, long service life, and other characteristics.

Our company has taken the lead in passing ISO9001 quality system certification, CE certification, and SGS certification, and was awarded Henan High tech Enterprise in 2022.

We can provide customized products, services, and solutions to meet the needs of customers in different industries, and have established long-term partnerships with customers from Southeast Asia, the Middle East, Africa, South America, Oceania, and other countries.

The company is located in Xinxiang City, Henan Province, China. It is only an hour and a half drive from Xinzheng International Airport. We provide a free shuttle service. We sincerely invite foreign friends to visit our company and have face-to-face exchanges to jointly promote development.

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee the quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.

Powder Grain Conveying Machine Vacuum Feeding Conveyor System

The TLCM vacuum feeder uses a vacuum pump to pump air, so that the inlet of the suction nozzle and the whole system are in a certain vacuum state. The powder and particles are sucked into the nozzle along with the outside air to form a material air flow, and then reach the hopper through the suction pipe. Separation of gas and material in the middle. The separated material enters the receiving equipment. Conveying and discharging are accomplished through the continuous opening and closing of the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is controlled by the control center.

The vacuum feeder is equipped with a compressed air blowback device. Every time the material is discharged, the compressed air pulse blows back the filter to knock down the powder adsorbed on the surface of the filter, so that the suction can operate normally.

PRODUCT ADVANTAGES

1-Reduce environmental and personnel pollution to materials and improve cleanliness.

2-It occupies a small space, and can complete the powder conveying in a narrow space, making the working space beautiful and generous, not limited by the distance.

3-The entire conveying process is carried out in a closed system, and no powder leakage will occur.

4-Easy to visually inspect, the equipment has no gaps or dead corners that are easy to accumulate materials, and the surface is easy to visually inspect.

5-Reduce labor intensity and improve work efficiency.

APPLICATION

TLCM vacuum conveying machine is extensively applied in pharmaceutical industry, food industry, chemical industry and agriculture. Vacuum feeding machine can be used to convey bulk pharmaceutical chemicals, powder material, granular material, mixed material, tablets, afterbirth pills, capsules, additives, raw materials, candy, afterbirth sugar pill, cocoa powder, gourmet powder, crystal, etc. This vacuum conveying machine can also be used to convey chemical raw materials, industrial raw materials, dyes, agricultural bulk material, etc .

FEATURES

1. The material suction nozzle entrance and the whole system of ZKS vacuum feeding machine are in a certain vacuum state. Powder or particle material and outside air can be suctioned into the material nozzle and form material air flow. Through the suction material tube, it reaches the hopper where air and material will be separated. After separation, material enters the material receiving equipment.

2. This vacuum conveying machine is installed with compressed air reverse blowing device. While putting material, compressed air pulse reversely blows the filter and fetches down the powder absorbed on the surface of filter, thus ensures material suction is in normal running.

MATERIALS USAGES SCENARIO

ABOUT TRANSPORTATION

After you place the order and pay the deposit, we will start to arrange the production and contact the ocean freight transportation agency to reserve the position. Two days before the end of production, you need to complete the final payment. Then, we inform the ocean cargo transportation agent company that it is ready to come to the factory to pull the goods to the port. On the day of delivery, we will send the customer the factory video and pictures, and mark the corresponding English name of each product and product parts with a marker to prevent the customer from not knowing what each part is after receiving the goods. At the same time, we will put the English version of the product instructions in the cargo box. We generally select freight forwarders with preferential prices for customers to deliver goods for you. The shipping method can be FOB or CIF. You can also choose EXW, and then contact the goods agent company yourself.

COMPANY PROFIL

Xinxiang Tianfeng Vibrating Machinery Co., Ltd. (formerly Xinxiang Tianfeng Vibrating Machinery Factory) is a comprehensive enterprise specializing in the research, development, manufacturing, and sales of mechanical equipment such as vibrating screen, separation, crushing, and conveying for more than 30 years. The company mainly produces Vibrating screens, ultrasonic vibrating screens, test screens, oscillating screens, linear screens, airflow screens, feeders, bucket elevators, conveying equipment, and other mechanical equipment. This equipment features stable and reliable operation, simple operation, convenient maintenance, low noise, low energy consumption, large output, and high precision; The screen mesh has the advantages of no blockage, no flying powder, no liquid leakage, etc. The products are widely used in food, medicine, chemical industry, metallurgy, abrasives, plastics, glass, paint, pollution control, and other industries, with high efficiency, large processing capacity, long service life, and other characteristics.

Our company has taken the lead in passing ISO9001 quality system certification, CE certification, and SGS certification, and was awarded Henan High tech Enterprise in 2022.

We can provide customized products, services, and solutions to meet the needs of customers in different industries, and have established long-term partnerships with customers from Southeast Asia, the Middle East, Africa, South America, Oceania, and other countries.

The company is located in Xinxiang City, Henan Province, China. It is only an hour and a half drive from Xinzheng International Airport. We provide a free shuttle service. We sincerely invite foreign friends to visit our company and have face-to-face exchanges to jointly promote development.

FAQ

1. Who are we?

Our headquarters is located in Henan, China, and our factory was established in 2002. At present, there are more than 100 workers, technical engineers, foreign trade sales personnel, and administrative personnel. The factory covers an area of more than 2000 square kilometers and is mainly engaged in vibrating screening and conveying and feeding equipment.

2. How do we guarantee the quality?

Always provide pre-production samples before mass production; Always carry out a final inspection before shipment.

3. What can you buy from us?

You can purchase a vibrating screen, roller screens, rotary screens, vacuum conveyors, mixer, and customized vibrating machinery and conveying equipment in our factory.

4. What are our strengths?

As one of the old enterprises in the screening industry, Tianfeng has provided a large number of screening equipment and systems at home and abroad. Mass production, rapid delivery, stable quality, affordable price, and excellent after-sales service have become the symbols of Tianfeng.

5. What services can we provide?

Accepted delivery conditions: FOB, CFR, CIF, EXW, CIP, FCA, CPT, DDP, express;

Accepted payment currency: USD, EUR, RMB;

Type of payment accepted: telegraphic transfer, letter of credit, express remittance, credit card, PayPal, Western Union remittance, cash, custody;

Oral: English, Chinese, French.

6. What information do we need to help you choose a perfect machine?

-Name and characteristics of raw materials.

-Purpose of use: remove impurities, filter, and grade.

-Processing capacity: kg/h, L/h.

-Raw material size: (mesh or mm).

-How many floors do you need?

-Voltage, frequency, phase (single-phase or three-phase) Note: You'd better send us the relevant pictures or materials you want to filter, which can ensure that we recommend the appropriate machine for you.